Projects

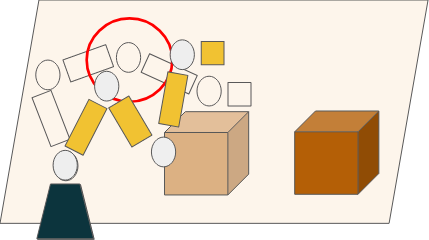

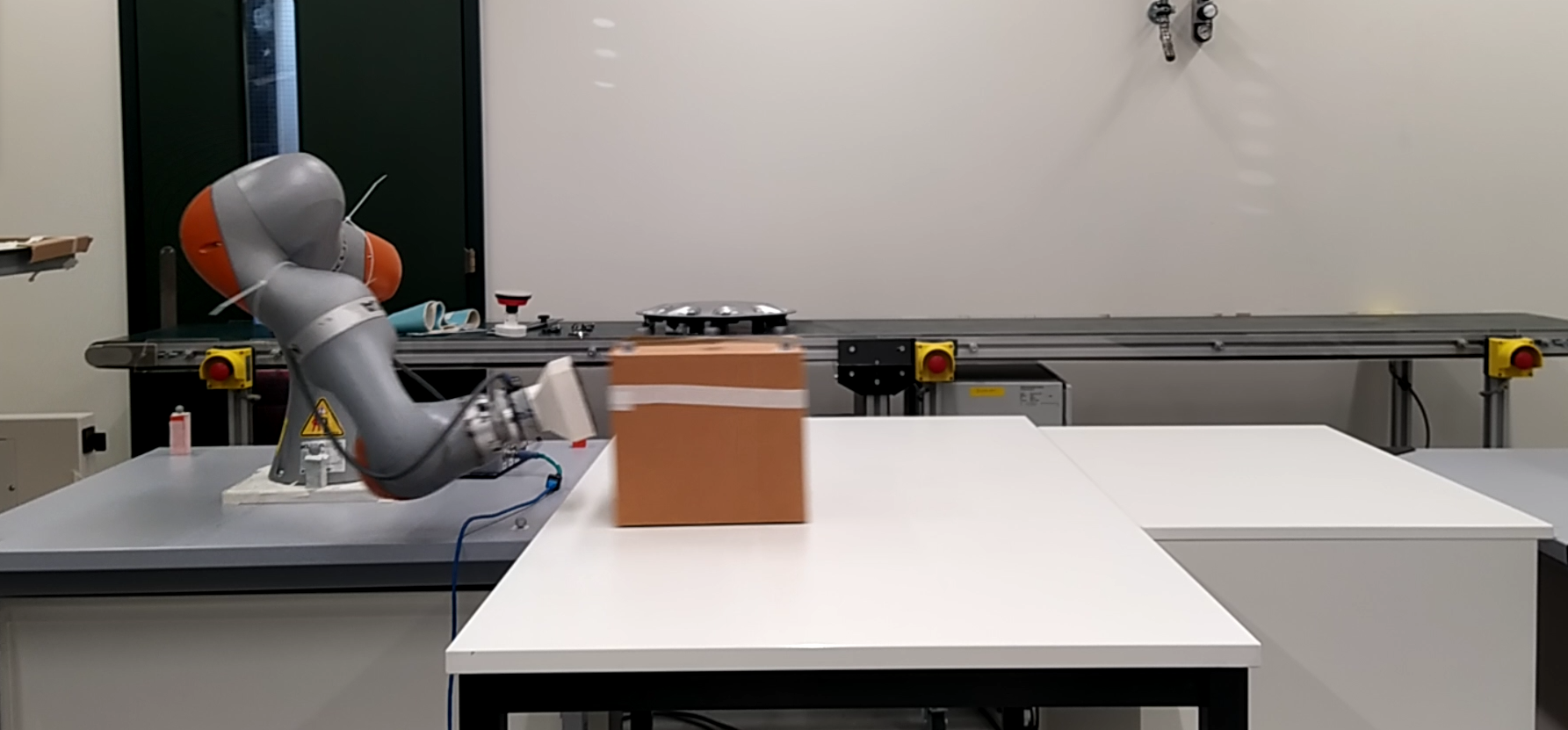

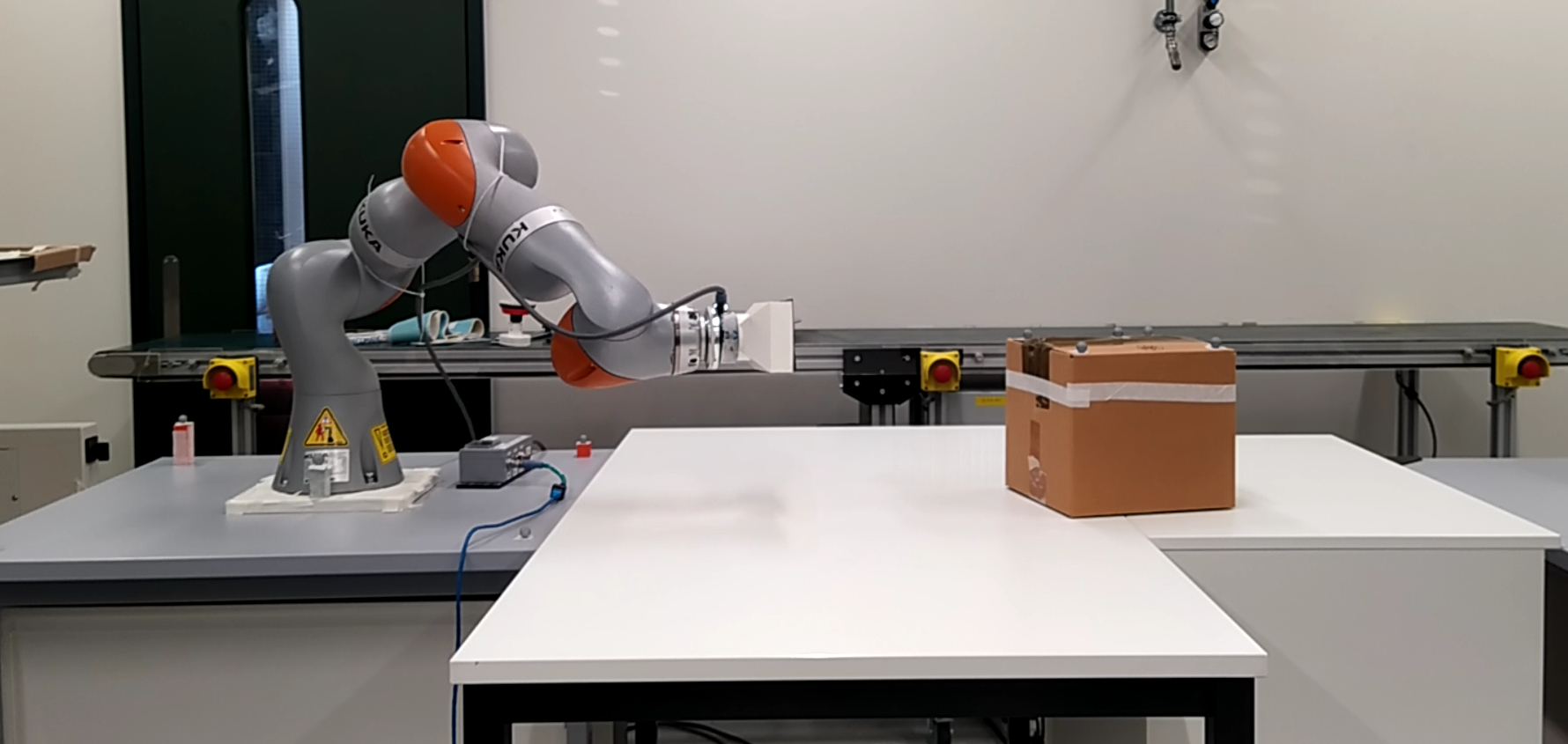

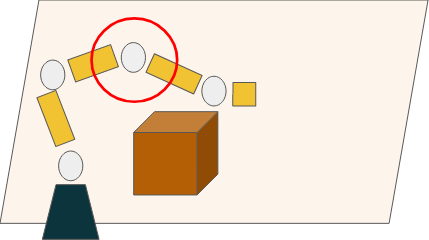

Hitting with different joints of a manipulator

Description:

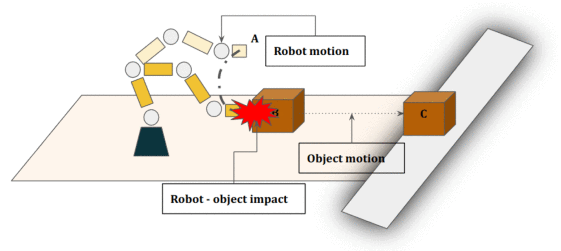

This project builds up the skill of impact aware non prehensile manipulation

through a hitting motion by allowing the robot arm to come in contact with the

environment with parts other than its end effector.

In tasks where directional effective inertia of a robot is important at the contact point,

it is useful to understand inertia not just at the end effector of the robot

but also at other points of the robot.

Hitting with other joints allows us to manipulate heavier objects since

the robot effective inertia is higher at joints other than its end effector.

We propose a methodology for selecting a hitting joint based on the hitting task requirements,

impact posture generation for the robot and a smooth generation of desired directional inertia values through a hitting motion.

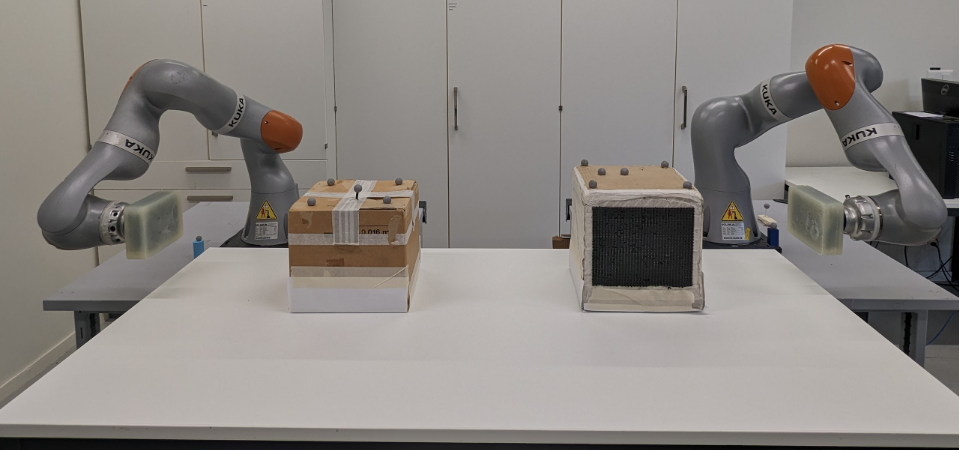

Automated Air Hockey Inspired Dual Arm Hitting Framework

Description:

This paper presents a data collection framework and a learning model to understand

the motion of an object after being subject to an impulse.

The data collection framework consists of an automated dual arm setup hitting an object to each other,

like a collaborative air-hockey game. The design of the system is further detailed in the system.

An impact aware extended Kalman filter is proposed for automation of the air-hockey setup which

approximates the discontinuous impulse motion equations through a hitting force model by balancing

the energies during collision. To capture the variance in the motion that stochasticity of friction introduces,

the errors in the controls for the hitting flux, we model the stochastic relationship between hitting impulse

and object's resulting displacement, using full density modeling. Further we show the application of the learnt

motion model for planning sequential hits with two or more robots, in a Golf-like principle, to let an object reach a location far beyond reach of any single robot.

Repeatable Motion Generation for a robot to hit an object

Description:

In this article, we propose a metric called hitting flux, which is used in the motion generation and controls

for a robot manipulator to interact with the environment through a hitting or a striking motion.

Given the task of placing a known object outside of the workspace of the robot, the robot needs

to come in contact with it at a nonzero relative speed. The configuration of the robot and the speed

at contact matter because they affect the motion of the object. The physical quantity called hitting flux

depends on the robot's configuration, the robot speed, and the properties of the environment.

An approach to achieve the desired directional preimpact flux for the robot through a combination

of a dynamical system for motion generation and a control system that regulates the directional inertia

of the robot is presented. Furthermore, a quadratic program formulation for achieving a desired inertia matrix

at a desired position while following a motion plan constrained to the robot limits is presented.

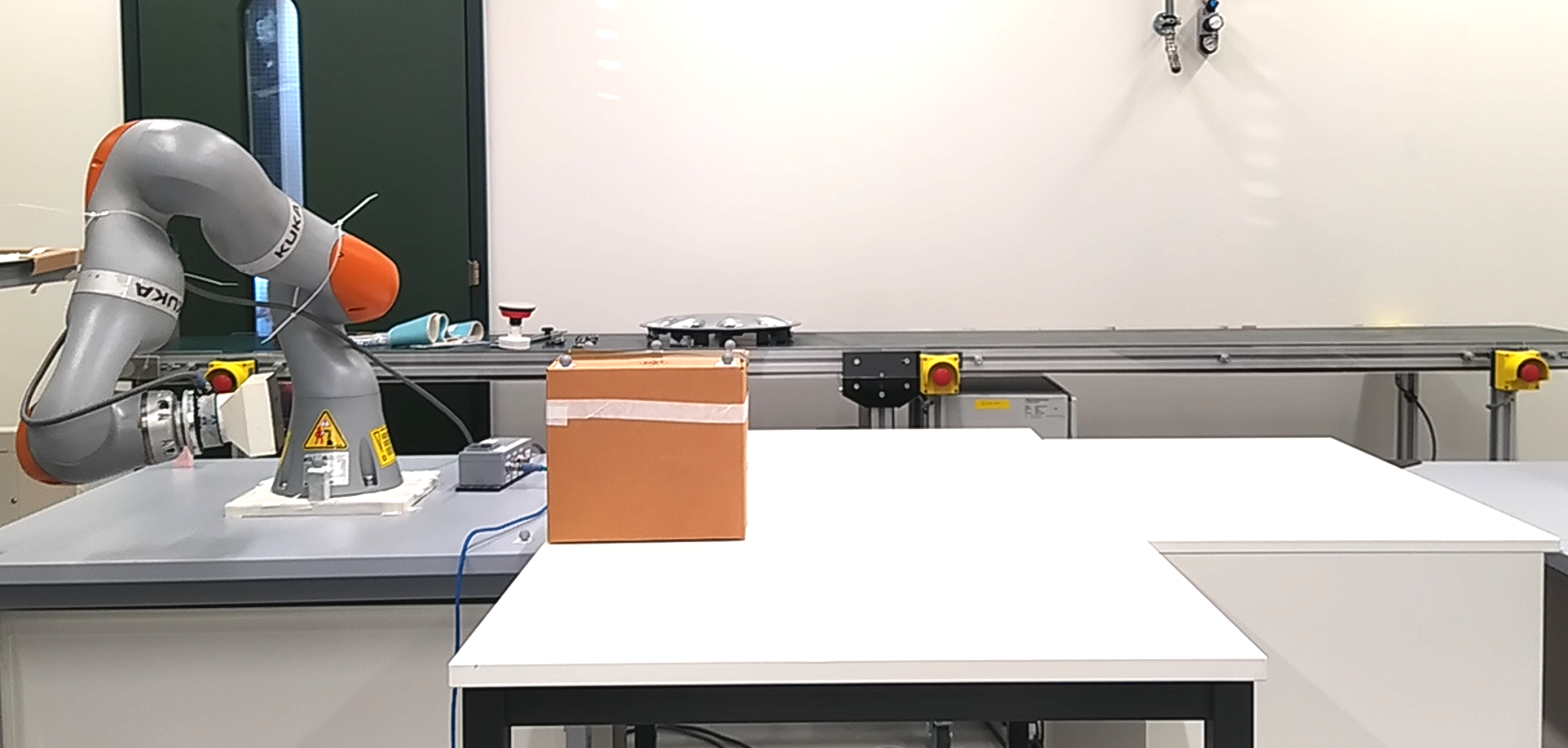

The system is tested for different scenarios in simulation showing the repeatability of the procedure

and in real scenarios with KUKA LBR iiwa 7 robot.

Learning to Hit through Dynamical Systems

Description:

This paper proposes a manipulation scheme based on learning the motion of objects

after being hit by a robotic end-effector. This allows for the object to be positioned

at a desired location outside the physical workspace of the robot.

An estimate of the object dynamics under friction and collisions is learnt and used

to predict the desired hitting parameters (speed and direction),

given the initial and desired location of the object.

Based on the obtained hitting parameters, the desired pre-impact velocity of the end-effector

is generated using a stable dynamical system. The performance of the proposed DS is validated in simulation

and and is used to learn a model for hitting using real robot. The approach is tested on real robot with a KUKA LBR IIWA robot.